製品&サービス情報

鋳鋼グローブ弁

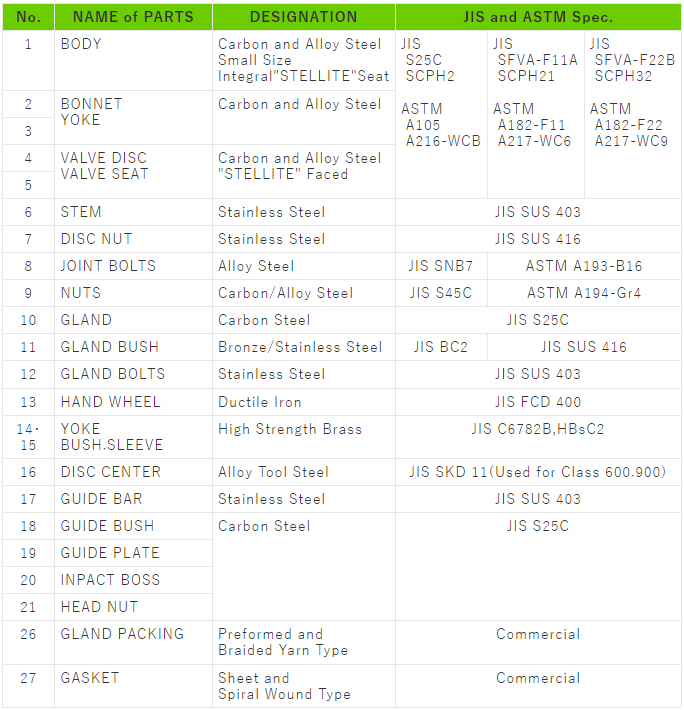

材料 MATERIALS

| No. | NAME of PARTS | DESIGNATION | JIS and ASTM Spec. | ||

|---|---|---|---|---|---|

| 1 | BODY | Carbon and Alloy Steel Small Size Integral"STELLITE"Seat |

JIS S25C SCPH2 ASTM A105 A216-WCB |

JIS SFVA-F11A SCPH21 ASTM A182-F11 A217-WC6 |

JIS SFVA-F22B SCPH32 ASTM A182-F22 A217-WC9 |

| 2 | BONNET YOKE |

Carbon and Alloy Steel | |||

| 3 | |||||

| 4 | VALVE DISC VALVE SEAT |

Carbon and Alloy Steel "STELLITE" Faced |

|||

| 5 | |||||

| 6 | STEM | Stainless Steel | JIS SUS 403 | ||

| 7 | DISC NUT | Stainless Steel | JIS SUS 416 | ||

| 8 | JOINT BOLTS | Alloy Steel | JIS SNB7 | ASTM A193-B16 | |

| 9 | NUTS | Carbon/Alloy Steel | JIS S45C | ASTM A194-Gr4 | |

| 10 | GLAND | Carbon Steel | JIS S25C | ||

| 11 | GLAND BUSH | Bronze/Stainless Steel | JIS BC2 | JIS SUS 416 | |

| 12 | GLAND BOLTS | Stainless Steel | JIS SUS 403 | ||

| 13 | HAND WHEEL | Ductile Iron | JIS FCD 400 | ||

| 14・15 | YOKE BUSH.SLEEVE | High Strength Brass | JIS C6782B,HBsC2 | ||

| 16 | DISC CENTER | Alloy Tool Steel | JIS SKD 11(Used for Class 600.900) | ||

| 17 | GUIDE BAR | Stainless Steel | JIS SUS 403 | ||

| 18 | GUIDE BUSH | Carbon Steel | JIS S25C | ||

| 19 | GUIDE PLATE | ||||

| 20 | INPACT BOSS | ||||

| 21 | HEAD NUT | ||||

| 26 | GLAND PACKING | Preformed and Braided Yarn Type |

Commercial | ||

| 27 | GASKET | Sheet and Spiral Wound Type |

Commercial | ||

材料 MATERIALS

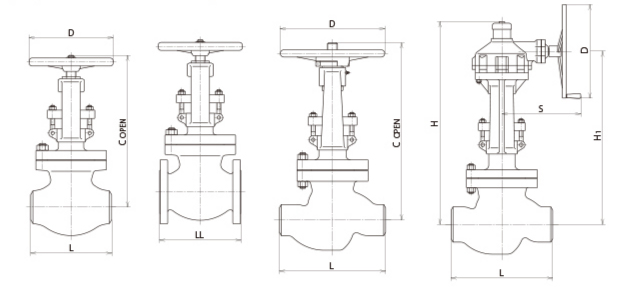

| Class Style | Nom.Size mm(in) |

L・LL | C | H | H1 | S | D | Gear Type |

Mass kg | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W L | WLL | ||||||||||

| CLASS150 | 670 | 65(2 1/2) | 216 | 440 | - | - | - | 200 | - | 28 | 35 |

| 80(3) | 241 | 495 | - | - | - | 250 | - | 38 | 46 | ||

| 100(4) | 292 | 565 | - | - | - | 300 | - | 60 | 69 | ||

| 125(5) | 356 | 615 | - | - | - | 355 | - | 92 | 105 | ||

| 150(6) | 406 | 690 | - | - | - | 400 | - | 125 | 138 | ||

| 200(8) | 495 | 875 | - | - | - | 500 | - | 210 | 228 | ||

| 250(10) | 622 | 960 | - | - | - | 500 | - | 315 | 340 | ||

| 300(12) | 698 | 1070 | - | - | - | 560 | - | 430 | 480 | ||

| 350(14) | 787 | 1200 | - | - | - | 630 | - | 610 | 660 | ||

| 400(16) | 914 | 1305 | - | - | - | 630 | - | 850 | 930 | ||

| 450(18) | 978 | - | 1530 | 1350 | 515 | 610 | BA-2 | 1100 | 1250 | ||

| 500(20) | 1092 | - | 1685 | 1450 | 555 | 760 | BA-3 | 1400 | 1650 | ||

| CLASS300 | 672 | 65(2 1/2) | 292 | 440 | - | - | - | 200 | - | 31 | 40 |

| 80(3) | 318 | 495 | - | - | - | 250 | - | 44 | 54 | ||

| 100(4) | 356 | 565 | - | - | - | 300 | - | 66 | 76 | ||

| 125(5) | 400 | 650 | - | - | - | 400 | - | 107 | 120 | ||

| 150(6) | 444 | 865 | - | - | - | 500 | - | 192 | 205 | ||

| 200(8) | 559 | 965 | - | - | - | 560 | - | 310 | 330 | ||

| 250(10) | 622 | 1090 | - | - | - | 630 | - | 470 | 510 | ||

| 300(12) | 711 | 1215 | - | - | - | 710 | - | 670 | 730 | ||

| 350(14) | 800 | - | 1475 | 1240 | 515 | 610 | BA-2 | 900 | 1000 | ||

| CLASS600 | 674 | 65(2 1/2) | 330 | 560 | - | - | - | 300 | - | 53 | 65 |

| 80(3) | 356 | 620 | - | - | - | 355 | - | 82 | 95 | ||

| 100(4) | 432 | 820 | - | - | - | 500 | - | 145 | 170 | ||

| 125(5) | 508 | 915 | - | - | - | 500 | - | 230 | 290 | ||

| 150(6) | 559 | 1035 | - | - | - | 630 | - | 340 | 400 | ||

| 200(8) | 660 | - | 1305 | 1130 | 515 | 610 | BA-2 | 590 | 680 | ||

| 250(10) | 787 | - | 1410 | 1225 | 515 | 610 | BA-2 | 885 | 1055 | ||

| 300(12) | 838 | - | 1640 | 1395 | 555 | 760 | BA-3 | 1320 | 1500 | ||

Dimensions in mm

注.

Wʟ…溶接型弁質量

Wʟʟ…フランジ型弁質量

…ハンマーブローハンドル型

…ギヤー操作型

NOTE:

Wʟ…Butt welding end valves, Mass apporx. kg

Wʟʟ…Flanged end valves, Mass apporx. kg

…denotes Hammerblow Handwheel Type

…denotes Gear Operated Type

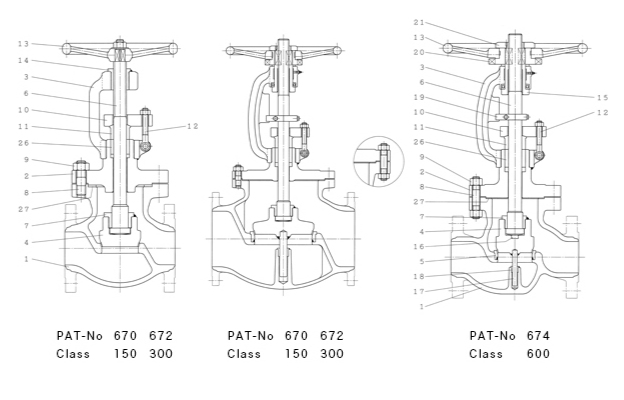

ハンドル取付部にあそびを設け回転衝撃力を利用し大きなハンドル操作力を得て締切力を保証します。衝突の原理により打撃回数に比例してエネルギーが蓄積されますので、通常の締切操作は数回の打撃に止めてください。またこの場合にはエネルギー効率を向上させるため弁棒非回転式を標準設計とします。

There is a play space in the handwheel attachment. This assures the tightness by obtaining a large operation force with the use of rotation impact force. With the principle of collision, energy is accumulated in proportion to the times of hammering. Thus, normal closing operation should be done only by several hammerings. In this case, non-rotation stem system becomes the standard design to improve the energy efficiency.

適用範囲 Application Table

| Size/Class | 150 | 300 | 600 |

|---|---|---|---|

| 100 | - | - | ◯ |

| 125 | - | - | ◯ |

| 150 | - | ◯ | ◯ |

| 200 | ◯ | ◯ | G |

| 250 | ◯ | ◯ | G |

| 300 | ◯ | ◯ | G |

| 350 | ◯ | G | - |

| 400 | ◯ | - | - |

| 450 | G | - | - |

| 500 | G | - | - |

注.

◯…ハンマーブローハンドル

G…ギヤー操作

NOTE:

◯…Hammerblow Handwheel

G…Gear Operated